You rely on your rolling cutter for smooth, precise cuts every time. But are you giving it the care it needs to last longer and work better?

Without proper maintenance, your cutter can become dull, stuck, or even damaged—making your projects harder and more frustrating. You’ll discover simple, effective tips to keep your rolling cutter sharp and ready to go. By following these easy steps, you’ll save time, avoid costly replacements, and get the clean cuts you want every time.

Keep reading to learn how to make your rolling cutter work like new again.

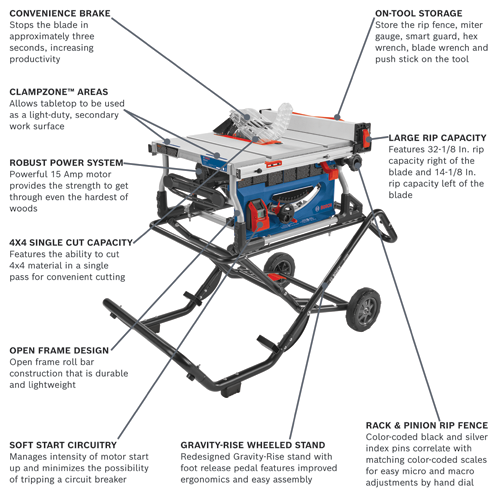

Credit: www.boschtools.com

Choosing The Right Rolling Cutter

Choosing the right rolling cutter is important for good cutting results. The right cutter helps you work safely and smoothly.

Look at different types and materials before buying. This helps you pick the best tool for your needs.

Types And Features

Rolling cutters come in several types. Each type has features for different cutting jobs.

- Standard cutters are good for light work and paper.

- Heavy-duty cutters handle thick materials like leather.

- Rotary cutters have a round blade that cuts smoothly.

- Ergonomic cutters reduce hand strain during use.

Pick a cutter with a sharp blade and comfortable handle. This makes cutting easier and safer.

Quality Materials

The material of the rolling cutter affects its strength and life. High-quality materials last longer and cut better.

Look for cutters made with stainless steel or carbon steel blades. These stay sharp and resist rust.

- Stainless steel blades are rust-resistant and durable.

- Carbon steel blades are very sharp and long-lasting.

- Handles made of strong plastic or metal last longer.

Cleaning Techniques

Keeping a rolling cutter clean helps it work better and last longer. Dirt and residue can make the blade dull or unsafe.

Use simple cleaning steps regularly to keep your cutter in good shape. Clean the blade and body carefully to avoid damage.

Regular Cleaning Routine

Clean your rolling cutter after every use. This stops sticky material buildup on the blade and handle. Wipe the blade with a soft cloth to remove dust and scraps.

Check the blade for stuck pieces and use a small brush to clear them out. Clean the handle and moving parts to keep the cutter smooth and safe.

- Wipe blade with a dry soft cloth

- Use a small brush for stuck debris

- Clean handle and joints regularly

- Store cutter in a dry place

Safe Cleaning Products

Choose mild cleaning products that do not harm metal or plastic parts. Avoid strong chemicals that can cause rust or damage. Soap and water work well for most cleaning needs.

Use rubbing alcohol for disinfecting the blade if needed. Apply it with a cloth and dry the cutter completely afterward. Avoid soaking the cutter in liquids to protect the blade and handle.

- Mild soap and warm water

- Soft cloths or sponges

- Small soft brushes

- Rubbing alcohol for disinfecting

- Avoid harsh chemicals and soaking

Proper Storage Solutions

Keeping your rolling cutter in good shape starts with proper storage. Storing it correctly stops damage and keeps it sharp.

Good storage habits make your cutter last longer and work better every time you use it.

Avoiding Moisture

Moisture can cause rust and dull the blade quickly. Keep your rolling cutter dry to avoid this problem.

Store your cutter in a dry place away from water or damp areas like bathrooms or basements.

- Use silica gel packs to absorb moisture inside storage boxes

- Wipe the blade dry after each use before storing

- Keep the cutter in a sealed container to block humidity

Safe Blade Storage

Protect the blade by storing it safely. This prevents accidents and keeps the blade sharp.

Use a blade cover or case made for rolling cutters. This stops the blade from touching hard surfaces.

- Always retract the blade if your cutter has a retractable feature

- Store blades separately if you have extra replacements

- Keep blades out of reach of children

Credit: www.amazon.sa

Sharpening The Blade

A rolling cutter blade needs to stay sharp for smooth cuts. Dull blades make cutting hard and unsafe.

Sharpening the blade keeps your rolling cutter working well and lasts longer.

Frequency Of Sharpening

Sharpen the blade often if you use the cutter a lot. Sharp blades cut cleanly and quickly.

Check the blade every few weeks or after heavy use. If the blade pulls or tears material, sharpen it.

- Sharpen after every 10-15 hours of cutting

- Sharpen when cuts look rough or uneven

- Sharpen if you feel more pressure while cutting

Tools For Sharpening

You need the right tools to sharpen a rolling cutter blade safely and well. Use fine sharpening tools.

Common tools include sharpening stones, diamond files, and strops. Each tool works for different blade types.

- Sharpening Stone:Smooths the blade edge evenly

- Diamond File:Good for harder blades and small chips

- Leather Strop:Polishes the blade to a sharp finish

- Protective Gloves:Keep your hands safe while sharpening

Inspecting For Wear And Tear

Regular inspection of your rolling cutter helps keep it safe and effective. Look for signs of wear and tear to know when to fix or replace parts.

Checking the blade and handle carefully can prevent accidents and poor cuts. Use simple steps to spot problems early.

Detecting Blade Dullness

A dull blade cuts poorly and can cause uneven edges. Check if the blade feels blunt or if it pulls on the material instead of slicing cleanly.

Look for chips or cracks on the blade. These signs mean the blade needs sharpening or replacement.

- Test cut on scrap material

- Watch for ragged edges

- Check for smooth rotation of the blade

- Inspect blade surface for damage

Checking Handle Integrity

The handle should feel firm and stable. Loose handles can cause loss of control and accidents.

Look for cracks, breaks, or worn spots on the handle. Make sure any screws or fasteners are tight and secure.

- Hold the handle and check for wobbling

- Inspect for cracks or splits in the material

- Ensure screws are not loose or missing

- Replace damaged handles immediately

Handling And Usage Practices

Maintaining a rolling cutter starts with proper handling and usage. Using the tool correctly keeps it sharp and safe.

Good habits prevent accidents and extend the cutter’s life. Learn the right grip and cutting surfaces for best results.

Correct Grip Techniques

Hold the rolling cutter firmly but not too tight. A steady grip helps control the blade and avoid slips.

Keep your fingers away from the blade path. Use your dominant hand to guide the cutter smoothly along the material.

- Hold the handle with your whole hand

- Keep your index finger near the blade guard

- Use your other hand to hold the material steady

- Do not press too hard; let the blade do the cutting

Safe Cutting Surfaces

Always cut on a surface that protects the blade and your work area. Use a self-healing cutting mat when possible.

A flat, stable surface prevents the cutter from slipping. Avoid cutting on glass, metal, or uneven surfaces.

- Use a self-healing cutting mat for best results

- Place the mat on a flat, stable table

- Do not cut directly on wood or glass

- Replace the mat when it gets too worn or damaged

Replacing Parts When Necessary

Maintaining a rolling cutter keeps it working well and safe. Replacing parts is key to good upkeep.

Knowing when to change parts helps avoid damage and keeps cuts clean and smooth.

Identifying Worn Parts

Check your rolling cutter often to find worn parts early. Look for dull blades and loose handles.

Parts that are cracked, bent, or rusty need replacing. Worn gears can make cutting hard or uneven.

- Dull or chipped blades

- Loose or broken handles

- Worn gears or rollers

- Rust on metal parts

- Cracks in plastic components

Sourcing Replacement Parts

Use parts made for your rolling cutter model. This keeps the tool safe and working well.

Look for parts at hardware stores or online shops that sell tool parts. Check part numbers before buying.

- Check the cutter’s manual for part numbers

- Buy from trusted stores or websites

- Compare prices and reviews

- Keep old parts for reference

Credit: thebeardclub.com

Regular Maintenance Schedule

Keeping a rolling cutter in good shape needs regular care. A set schedule helps avoid breakdowns.

Check the cutter often to find problems early. This keeps it working well for a long time.

Creating A Maintenance Log

A maintenance log records all checks and repairs. It helps track what was done and when.

Use the log to write dates, parts checked, and any fixes made. This makes future work easier.

- Record date of maintenance

- Note parts inspected or replaced

- Write down any problems found

- Include who did the maintenance

Benefits Of Routine Checks

Routine checks keep the cutter safe and reliable. They help catch small issues before they grow.

Regular inspections also improve cutting quality. The cutter runs smoothly and lasts longer.

- Prevent unexpected breakdowns

- Ensure consistent cutting performance

- Extend the life of the cutter

- Save money on major repairs

Frequently Asked Questions

How Often Should I Clean My Rolling Cutter?

Clean your rolling cutter after every use to prevent debris buildup. Regular cleaning ensures smooth operation and extends tool lifespan.

What Lubricant Is Best For Rolling Cutters?

Use a light machine oil or specialized rolling cutter lubricant. Proper lubrication reduces friction and keeps the cutter running efficiently.

How Do I Sharpen A Rolling Cutter Blade?

Sharpen blades using a fine-grit sharpening stone or professional sharpening service. Maintain the original blade angle for optimal cutting performance.

Can I Replace Rolling Cutter Blades Myself?

Yes, most rolling cutters have easily replaceable blades. Follow the manufacturer’s instructions carefully to ensure safe and correct installation.

Conclusion

Maintaining a rolling cutter keeps it sharp and lasts longer. Clean it after each use to avoid rust and dirt. Check the blade often and replace it if dull. Store the cutter in a dry place to protect it. Regular care saves money and improves safety.

Small steps make a big difference in performance. Keep your rolling cutter ready for any cutting task. Simple habits lead to better results every time.