You rely on your rolling cutter to get precise, clean cuts every time. But without proper care, it can quickly lose its edge and effectiveness.

Imagine struggling through a project because your cutter drags or tears the material—frustrating, right? The good news is, maintaining your rolling cutter is easier than you think. You’ll discover simple, practical steps to keep your tool sharp and working smoothly.

Keep reading, and you’ll save time, effort, and avoid costly mistakes on your next project.

Choosing The Right Rolling Cutter

Choosing the right rolling cutter is important for good work results. A proper cutter helps you cut smoothly and safely.

There are different types of rolling cutters. You must know what fits your needs before buying one.

Types Of Rolling Cutters

Rolling cutters come in many styles for different uses. Some are made for fabric, others for paper or leather.

Here are common types you may find:

- Standard rotary cutters with round blades

- Ergonomic cutters with comfortable handles

- Specialty cutters for heavy materials

- Mini cutters for small, detailed work

Factors To Consider

Think about what you need before picking a cutter. Size, blade type, and safety features matter.

Consider these points:

- Material you will cut most often

- Blade sharpness and durability

- Comfort of the handle for long use

- Safety locks to prevent accidents

- Ease of blade replacement

Credit: www.ebay.com

Basic Maintenance Practices

Keeping your rolling cutter in good shape helps it work well. Regular care can make it last longer.

Simple maintenance keeps the blade sharp and safe to use. This guide covers key cleaning and storage tips.

Cleaning The Blade

Clean the blade after each use to remove dirt and glue. Use a soft cloth to wipe it gently.

For sticky residue, apply a small amount of rubbing alcohol. Avoid water, as it can cause rust.

- Unplug or remove the blade for safety

- Use a soft brush to clear dust

- Apply rubbing alcohol on a cloth to clean sticky spots

- Dry the blade completely before storing

Proper Storage Techniques

Store the rolling cutter in a dry, cool place. Avoid humid areas to prevent rust and damage.

Keep the blade covered or inside its case. This protects it from dust and accidental cuts.

- Use the blade cover or a protective sheath

- Place the cutter in a toolbox or drawer

- Keep it away from direct sunlight

- Store out of reach of children

Sharpening The Blade

A rolling cutter blade needs regular sharpening to work well. A sharp blade cuts cleanly and saves effort.

Keeping the blade sharp helps you finish projects faster and with better results.

Signs It’s Time To Sharpen

Notice these signs to know when your rolling cutter blade needs sharpening. Ignoring them can damage your materials.

- The blade pulls or drags instead of cutting smoothly.

- Edges of your cuts look rough or torn.

- You need extra pressure to cut through materials.

- The blade skips or jumps when cutting.

- Material frays along the cut line.

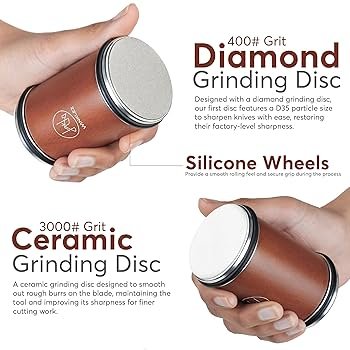

Tools For Sharpening

Use the right tools to sharpen your rolling cutter blade safely and effectively. Some tools work better for small blades.

- Diamond sharpening stone: fine and easy to control for small blades.

- Sharpening rod: good for quick edge touch-ups.

- Fine grit sandpaper: use gently on blade edges.

- Blade sharpener tool: designed for rotary blades.

- Soft cloth and oil: clean and protect blade after sharpening.

Replacing The Blade

Maintaining your rolling cutter is important for safe and clean cuts. One key task is replacing the blade when it gets dull.

Knowing when and how to change the blade keeps your cutter working well and prevents damage to materials.

When To Replace

Replace the blade if you notice it cutting poorly or snagging materials. Dull blades make rough or uneven cuts.

Also change the blade if it is chipped, bent, or rusted. A damaged blade can be unsafe to use.

- Blade cuts unevenly or drags

- Blade edges are chipped or bent

- Blade shows signs of rust or corrosion

- Blade causes frequent material tearing

Steps For Replacement

First, make sure your rolling cutter is on a flat surface and clean. Remove any debris around the blade area.

Use the tool that came with your cutter to loosen the blade holder screw or knob. Keep the parts safe.

- Remove the old blade carefully to avoid cuts

- Place the new blade in the correct position

- Tighten the blade holder securely but do not over-tighten

- Test the cutter on scrap material to check the new blade

Always handle blades with care and wear protective gloves if needed. Dispose of old blades safely to avoid injuries.

Safety Precautions

Maintaining a rolling cutter requires care and attention. Safety should be your top priority to avoid injuries.

Follow simple safety steps to keep yourself and others safe while handling the cutter.

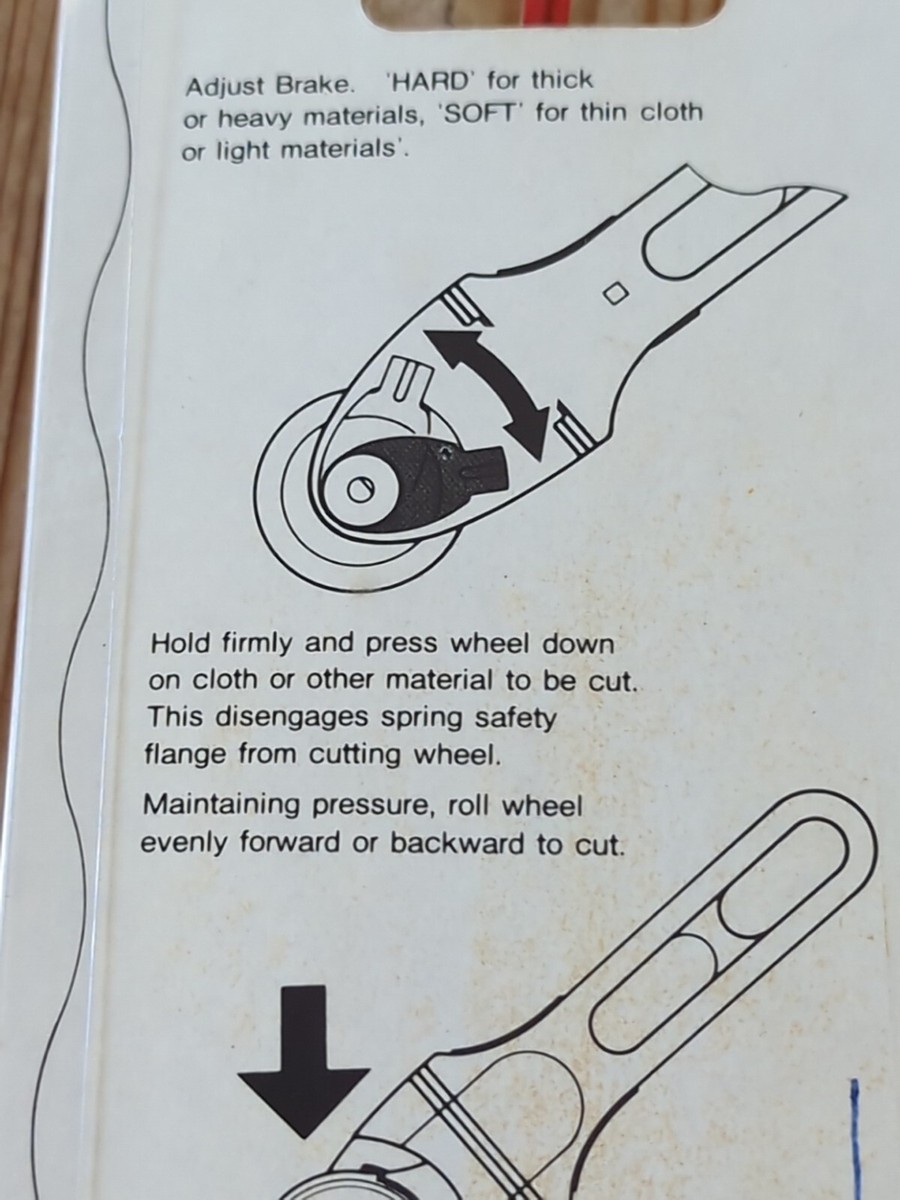

Handling The Cutter Safely

Always hold the rolling cutter by its handle. Keep fingers away from the blade at all times.

Use slow and steady movements to prevent slips. Do not apply too much pressure on the cutter.

- Keep the blade covered when not in use

- Do not use the cutter if the blade is dull or damaged

- Store the cutter in a safe place out of children’s reach

- Cut on a stable surface to avoid accidents

Protective Gear

Wear protective gloves to protect your hands from cuts. Gloves also improve your grip on the cutter.

Safety glasses protect your eyes from flying debris. Always wear them when cutting tough materials.

- Cut-resistant gloves help prevent injuries

- Safety glasses shield eyes from small particles

- Wear long sleeves to protect your arms

- Keep your work area clean and well-lit

Troubleshooting Common Issues

Maintaining your rolling cutter is important to keep it working well. This guide helps you fix two common problems. Follow these tips to solve issues quickly.

We will look at how to clear a jammed cutter and how to fix uneven cuts. Each section gives simple advice for better results.

Jammed Cutter

A jammed cutter stops your tool from moving. Dirt, fabric threads, or dull blades cause jams. Check the cutter often to avoid damage.

- Turn off and unplug the cutter before cleaning.

- Remove any stuck fabric pieces carefully.

- Use a small brush to clear dust and threads.

- Lubricate the moving parts with light oil.

- Sharpen or replace the blade if it is dull.

Uneven Cuts

Uneven cuts happen when the blade or surface is not set right. This problem makes your work look rough and unprofessional.

| Cause | How to Fix |

| Dull blade | Sharpen or replace the blade |

| Improper blade alignment | Adjust the blade to be straight and secure |

| Uneven cutting surface | Check and level the surface before cutting |

| Too much pressure | Use consistent, gentle pressure when cutting |

Regular Maintenance Schedule

Maintaining your rolling cutter regularly keeps it working well. A set schedule helps avoid damage and saves time.

Follow these weekly and monthly steps to keep your cutter sharp and safe for use.

Weekly Care Tasks

Perform these tasks every week to keep the rolling cutter in good shape. They help prevent buildup and wear.

- Clean the blade after each use with a soft cloth.

- Check the blade for any chips or dull spots.

- Lubricate the moving parts with light oil.

- Inspect the handle for cracks or loose screws.

- Store the cutter in a dry, safe place.

Monthly Checks

Monthly checks are deeper inspections to ensure long-term performance and safety.

| Check Item | What to Do | Reason |

|---|---|---|

| Blade Sharpness | Sharpen the blade or replace if needed | Ensures clean cuts and reduces effort |

| Blade Alignment | Adjust the blade alignment carefully | Prevents uneven cutting and damage |

| Fasteners | Tighten all screws and bolts securely | Keeps parts stable during use |

| Safety Guard | Inspect and clean the guard | Protects the user from injury |

| Overall Condition | Look for rust, wear, or damage | Maintains tool durability and safety |

Credit: thebeardclub.com

Credit: thebeardclub.com

Frequently Asked Questions

How Often Should I Clean A Rolling Cutter?

Clean your rolling cutter after every use. Removing debris prevents buildup and ensures smooth operation. Regular cleaning extends the tool’s lifespan and maintains cutting precision.

What Lubricant Is Best For Rolling Cutters?

Use light machine oil or specialized cutter lubricant. Avoid heavy oils that attract dirt. Regular lubrication reduces friction and prevents rust, keeping the cutter sharp and efficient.

How Do I Sharpen A Rolling Cutter Blade?

Use a fine file or sharpening stone. Follow the blade’s original angle carefully. Sharpening keeps the blade effective, improves cutting quality, and prevents damage during use.

When Should I Replace A Rolling Cutter Blade?

Replace the blade if it’s chipped, dull, or rusted. A sharp blade ensures clean cuts and safety. Regular inspection helps determine the right time for replacement.

Conclusion

Maintaining a rolling cutter keeps it sharp and safe. Clean it regularly to avoid rust and dirt buildup. Check the blade for damage and replace when needed. Lubricate moving parts to ensure smooth cutting action. Store the cutter in a dry place after use.

Small efforts prevent big problems later. A well-kept cutter saves time and effort. Follow these simple steps to keep your tool ready. Easy care leads to better results every time. Keep your rolling cutter working like new.